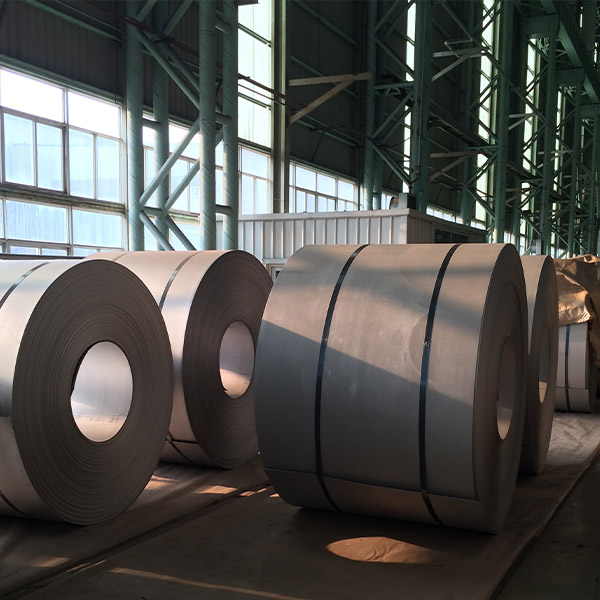

Ikhoyili yensimbi egoqiwe eshisayo ePickling

Ubukhulu

Ubukhulu bepuleti yensimbi kufanele buhlangabezane nezidingo zethebula "Ubukhulu kanye Nemininingwane Yamapuleti Ensimbi Eyizingqimba Ezishisayo (Ecashunwe ku-GB/T709-1988)".

Usayizi womugqa wensimbi kufanele uhlangabezane nezidingo zethebula elithi "Ubukhulu kanye Nezicaciso Zomcu Wensimbi Ogoqiwe Oshisayo (Ocashunwe ku-GB/T709-1988)".

Ububanzi bepuleti lensimbi nakho kungaba yinoma yimuphi usayizi we-50mm noma ukuphindaphinda kuka-10mm.

Ubude bepuleti yensimbi yinoma yimuphi usayizi we-100mm noma ukuphindaphinda kuka-50mm, kodwa ubude obuncane bepuleti lensimbi enobubanzi obungaphansi noma obulingana no-4mm akumele bube ngaphansi kuka-1.2m, futhi ubude obuncane bepuleti yensimbi enogqinsi olungaphezu kuka-4mm akumele bube ngaphansi kuka-2m.

Ngokwezidingo, ukushuba kwepuleti lensimbi ngaphansi kuka-30mm, isikhawu sokuqina singaba ngu-0.5mm.

Ngokwezidingo, ngemva kokuxoxisana phakathi komphakeli nomthengi, amapuleti ensimbi nemicu yamanye amasayizi anganikezwa.

Ukucaciswa

Ubukhulu obujwayelekile:0.8, 1.0, 1.2, 1.5, 1.8, 2.0, 2.35, 2.45, 2.50, 2.70, 2.75, 2.8, 2.9, 2.95, 3.0, 3.25, 3.3, 3.8, 3.5, 3.8, 3. 3.95, 4, 4.25 , 4.5, 4.7, 4.75, 5, 5.5, 5.75, 6, 6.75, 7, 7.5, 7.75, 8, 8.75, 9, 9.5, 9.75, 0.51, 10, 10, 10

Imikhiqizo Eyinhloko

I-Hot rolling eqhubekayo ingahlukaniswa ibe yinsimbi evamile ye-carbon structural, insimbi ephansi ye-alloy, nensimbi ye-alloy ngokusho kwempahla nokusebenza kwayo. Ngokusebenzisa kwazo okuhlukene, zingahlukaniswa zibe: insimbi eyenza ebandayo, insimbi yesakhiwo, insimbi yesakhiwo yezimoto, insimbi yesakhiwo engagqwali, insimbi yesakhiwo, isilinda segesi eshiselwe kanye nensimbi yomkhumbi wokucindezela, insimbi yepayipi, njll.

Inqubo Yokukhiqiza

Iyunithi yepuleti eligoqiwe elishisayo elinediphu isebenzisa inqubo yokuthungatha ye-Sendzimir ethuthukisiwe, futhi impahla eluhlaza ngamakhoyili afakwe emanzini anosawoti agingqiwe ashisayo. Inqubo yokukhiqiza imi kanje:

Ikhoyili efakwe emanzini anosawoti egoqwe ashisayo → ukuqaqa → ukusika ikhanda nomsila → i-welding → i-loop yokungena → isithando somlilo esivundlile sase-Sendzimir esilungisiwe → ukugqugquzelwa kwediphu elishisayo → ukupholisa ngemva kokucwecwa → igeji yogqinsi lwezinki → ukushelela nokuqondisa → ukuphathwa kwetafula lokuhlola → Ithebula lokuhlola → Ithebula lokuhlola → Ithebula lokuhlola ukupakisha → Iqedile ukugcina umkhiqizo.

isibonisi somkhiqizo